We’ve spent the last year helping our clients spotlight all the ways they’ve pivoted their operations and innovated to meet the needs of our new world. One client that has been recognized for the many ways they’ve supported the industry and local and global community this past year has been Digi-Key Electronics.

Right away when the ventilator shortages began in early 2020, Digi-Key teamed up with physicians at the University of Minnesota, and several other local companies, to help develop the Coventor, the first ventilator approved for use under the FDA’s Emergency Use Authorization for the COVID-19 outbreak. The system was built for rapid deployment, and specifications were shared as an open-source design, virtually unheard of in the medical device field, in order to increase availability of mechanical ventilation worldwide, even in low resource areas.

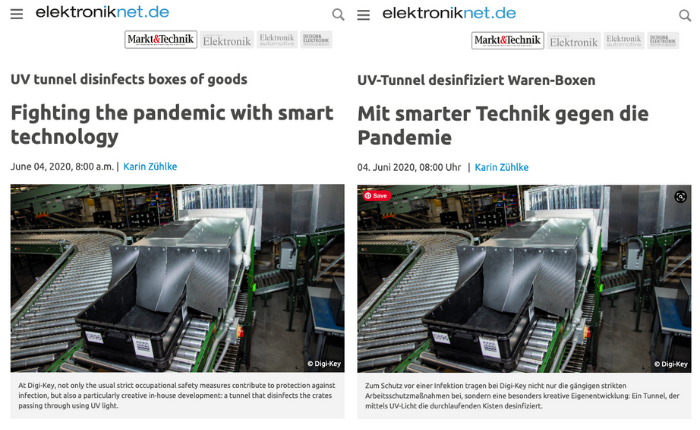

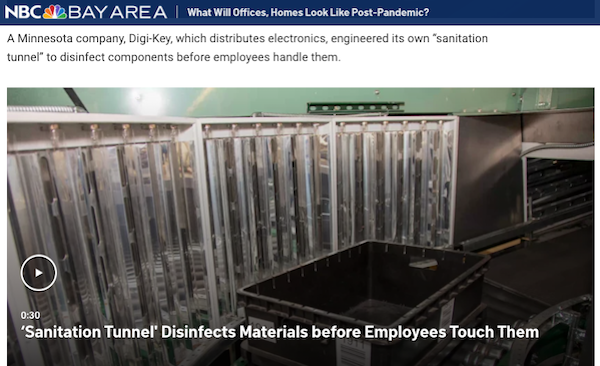

While one team of Digi-Key’s engineers were working on the Coventor, another team was simultaneously inventing new technology for their own internal operations, to disinfect the thousands of totes that carry product through the Digi-Key warehouse daily.

Digi-Key provides top technology, med tech, automotive, IoT and up-and-coming companies around the world with access to more than 11.5 million electronic components. As a result, nearly 8,000 plastic totes travel throughout Digi-Key’s 1 million-square-foot distribution center every day, transporting products through the picking, shipping and receiving departments. Employees in the product distribution center interact with the totes multiple times per day, and in the beginning of the pandemic little was known about how the virus was transferred and carried, so disinfecting everything that was touched in an efficient manner was no small task.

In record time, Digi-Key engineers developed and implemented a tunnel that uses UV light to kill 99.99 percent of the organisms on the totes, drastically reducing contact and spread of the virus for Digi-Key employees. And to this day, there has been no known spread of COVID-19 within Digi-Key’s facilities, thanks in part to the UV tunnel innovation, as well as the company’s stringent social distancing and disinfecting policies, and many other precautions put into place.

Bellmont Partners shared these innovative and unique pandemic solutions widely with media locally, nationally and globally, and they were covered everywhere from the Thief River Falls Times to the Star Tribune, MPR, NBC affiliates around the country, Industry Week, FOX News, and in several prominent industry publications in Europe and Asia.

While not the stories we expected to tell on behalf of Digi-Key last year, we’re proud to support their innovation, and delighted to help them be recognized on a global level for the many ways they’ve supported their employees, the electronics industry and the world in these challenging times. From being named a Tekne finalist in the COVID-19 Community Response category to a COVID HERO award from the Institute for Engineering in Medicine (IEM) and an Inc. Best in Business 2020 honoree, their community response to the pandemic has been felt on an international scale.

Digi-Key is enabling the world’s ideas on a daily basis, and we’re proud to support them in sharing the many ways they fuel global innovation, but we’re especially honored to have partnered with them on sharing these lifesaving innovations.